Saƙa

Webbing yana saƙa da saƙa.Zaren da aka murɗe ana murɗe shi zuwa cikin ƙugiya (reel), sa'an nan a naɗe saƙar a cikin ƙugiya a sanya shi a kan maƙarƙashiya.A cikin 1930s, an ƙaddamar da katakon katako da aka zana da hannu da kuma ɗorawa na ƙarfe na ƙarfe.A farkon shekarun 1960, an mayar da 1511 loom ɗin zuwa maƙala, wanda har yanzu ana amfani da shi a yau.Saboda fadin bel din karami ne, hanyar saƙa ta bambanta, akwai tushen guda ɗaya, saiwoyin biyu, da yawa na tushen, akwai nau'i ɗaya, akwai nau'i biyu.

A shekara ta 1967, ƙungiyar binciken ribbon mara motsi tare da ma'aikata a matsayin babban jiki ya yi nasarar tsarawa da kuma kera na'ura mai sauri guda ɗaya maras nauyi, wanda ya gane saƙar ribbon maras motsi, ya rage aikin, ya mamaye wani ƙaramin yanki, kuma ya inganta yawan aiki, wanda ya rage yawan aiki. aiki ne na farko a tarihin fasahar kintinkirin kasar Sin.

A cikin shekarun 1970s, saboda shaharar ribbon ci gaba da rini da injuna, sarrafa ribbon ya bunƙasa tun daga rini na farko da saƙa na gargajiya zuwa rini da rini na farko, saƙa na farko da bleaching, da kuma ci gaba da gamawa da guga.Fasahar Ribbon ta shiga sahu na samar da injina.A farkon shekarun 1980, Switzerland, Italiya da Tarayyar Jamus sun gabatar da injunan sakar bel mai sauri mara matukin jirgi, injinan guga, injinan nannade, injinan warping da dai sauransu.Kuma fasahar ribbon ta shiga wani sabon mataki na ci gaba.

Ci gaban fasahar yanar gizo ya haifar da haɓaka samfuran.A shekarar 1979, an samu nasarar samar da bel din roba na farko na SD9-9 na kasar Sin, wanda hakan ya kawo karshen tarihin dogaro da shigo da kayayyaki daga kasashen waje.1980 ɓullo da SD-81A da B nau'in roba ingot bel, tare da taushi, bakin ciki, karfi, kananan elongation, kananan tasiri, gajere da lebur hadin gwiwa halaye.A farkon shekara ta 1990, an yi nasarar samar da bel ɗin aminci na mota na gwaji na Santana.Bayan fiye da shekaru biyu na bincike da samar da gwaji, ingancin samfurin ya kai matsayin QC49-92 da TL-VW470.

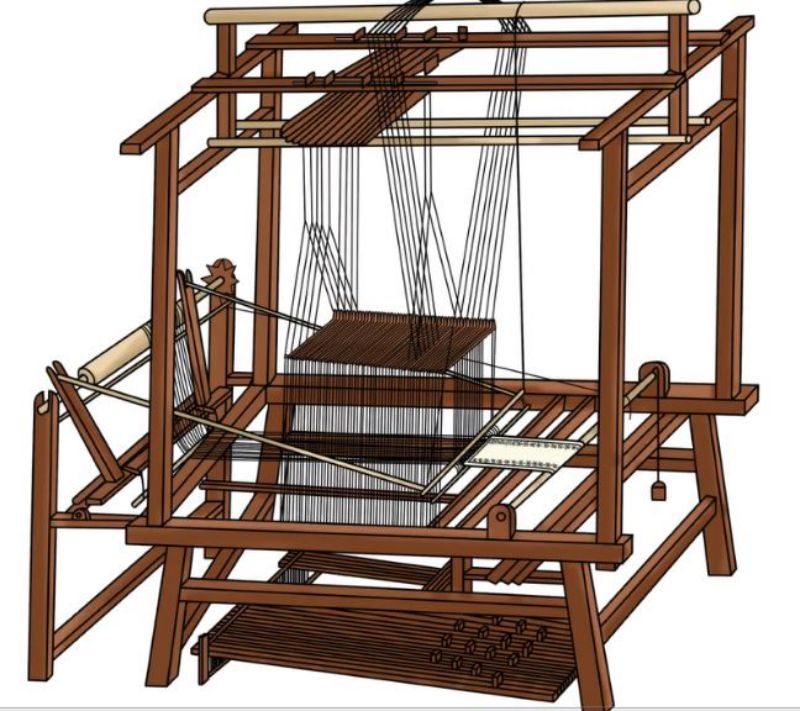

Saƙa (ingot saƙa)

Bayan an raunata ganga da saƙa don samar da bututu, sai a sanya su a cikin kafaffen tushe na haƙori na injin sakawa.Bututun saƙar yana jujjuya tare da waƙa-8 kuma yana jan yadudduka a tsakanin juna.Yawanci adadin ingots yana da ma'ana, ribbon yana tubular, adadin ingots ba shi da kyau, kuma ribbon yana da lebur.An yi amfani da tsarin saƙar tun daga tsohuwar kasar Sin, kuma adadin sanduna ya bambanta daga 9 zuwa 100 dangane da kayan aiki.Babban tsarin saƙa shine: bleaching, winding, weaving, doffing, yankan, marufi.Tun daga shekara ta 1960, an aiwatar da sabbin fasahohi da yawa a cikin injin ɗin, musamman waɗanda suka haɗa da faɗaɗa diamita na farantin peach, shigar da na'urorin dakatarwa ta atomatik don karya igiyoyin roba, da maye gurbin ƙarfe na ƙarfe da nailan.Haɓaka waɗannan kayan aikin ya haɓaka saurin zuwa 160 ~ 190 RPM, ƙimar tsaye ta ninka sau biyu, kuma ingancin samfurin ya inganta sosai.

Kuna iya saƙa ba kawai yanar gizo ba, har ma da igiya.Tubular bel wani nau'i ne na igiya da aka yi wa katsalandan, diamita na 1 ~ 4cm ana kiranta igiya ko layin igiya, diamita fiye da 4cm ana kiranta igiya, diamita na fiye da 40cm kuma ana kiransa igiya ko USB.A cikin 1989, masana'antar ta gabatar da kayan aikin layin samar da kebul na Jafananci, a shekara ta gaba samar da kebul na polypropylene stereotyped, ya sami lambar yabo ta kasa ta azurfa.

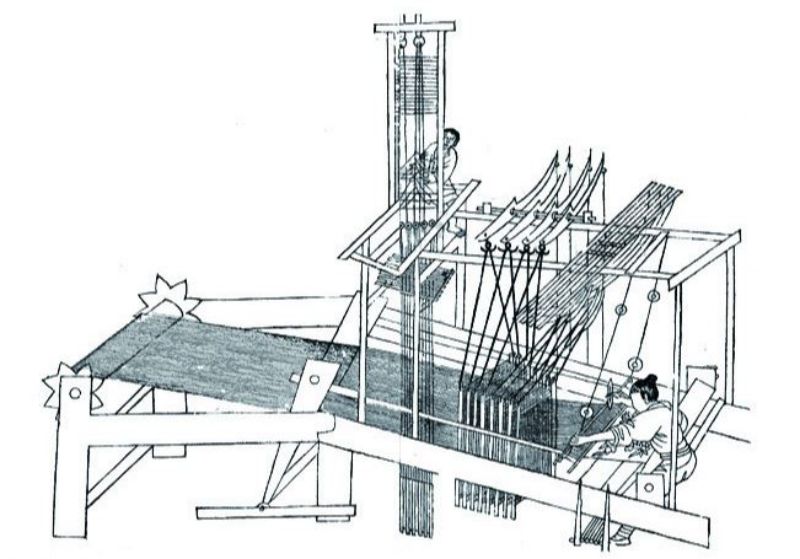

saka

A cikin shekarun 1970s, an yi amfani da fasahar saƙa da saƙa mai yawa a cikin yanar gizo.A cikin 1973, an yi nasarar samar da gwaji na saƙa na nailan m bel.A cikin 1982, ƙaddamar da na'ura na Italiyanci na crochet, fasaha mai zurfi, samfurori masu yawa, musamman dacewa da kayan ado na bakin ciki, irin su yadin da aka saka, igiyoyi na roba, allon taga, bel na ado da sauransu.Babban tsari shine: bleaching - winding - weaving - ironing - packing.

Kafin shekarun 1970s, bututun wuta ba komai ba ne ta hanyar injin kwance, tare da babban diamita da ƙarancin fitarwa.A cikin rabin na biyu na 1974, bisa ga ka'idar saƙa, masana'antar ta shirya rukunin bincike na saƙar bututun billet, ta amfani da warp da weft interweaving, dogaro da madauki yarn yayin aiwatar da madauki, ta amfani da ganga allura da daidaita baka na zaren madauki don haɗa warp ɗin da aka haɗa tare da saƙa a cikin gaba ɗaya, ta yadda ya zama masana'anta da aka saƙa da tubular tare da suturar saƙa da rigar warp.Matsayin fasahar samar da bututun ruwa mai rufi da kuma bututun wuta mai matsa lamba yana kan gaba a kasar.

Lokacin aikawa: Dec-06-2023